Mining Plate

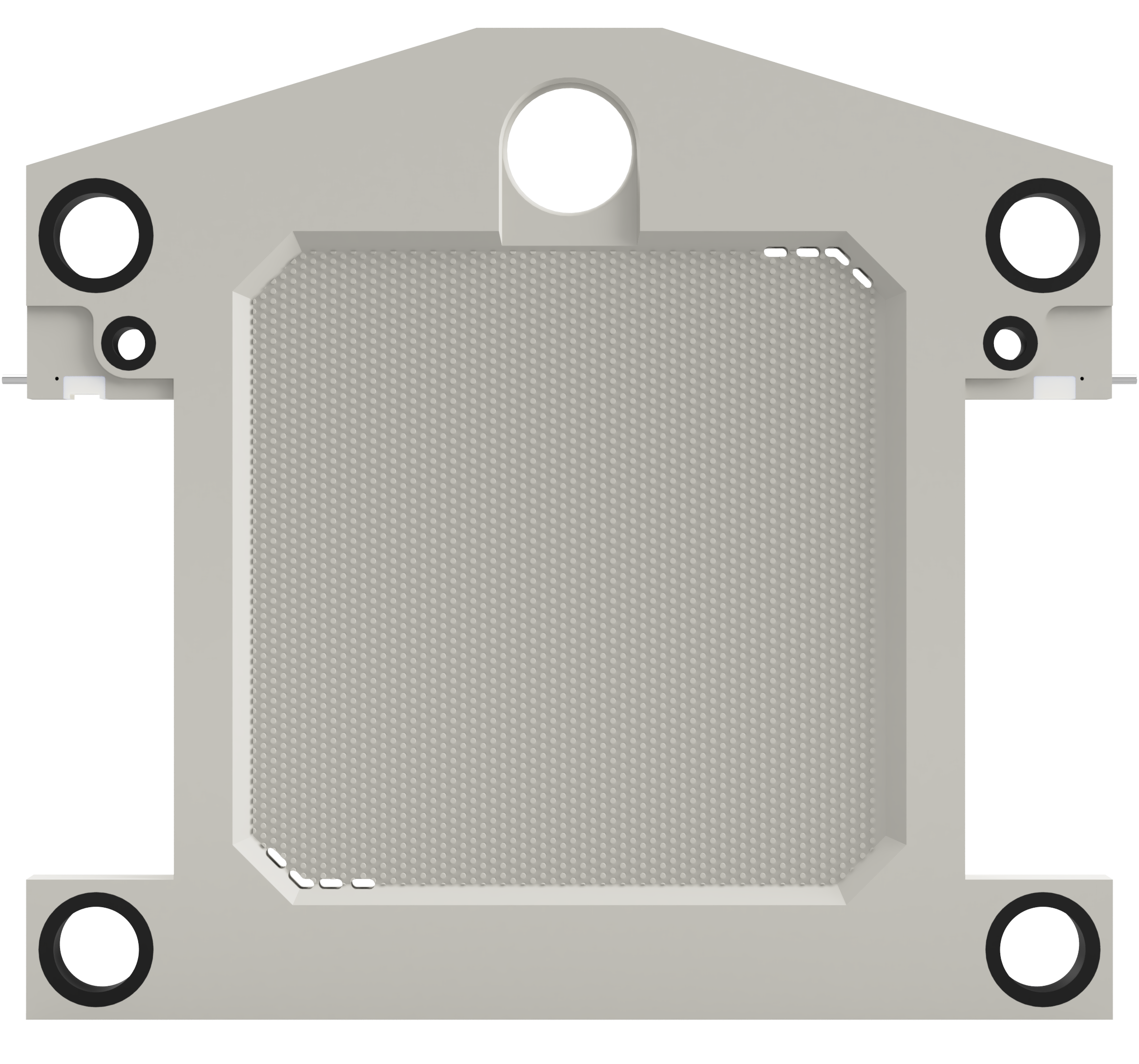

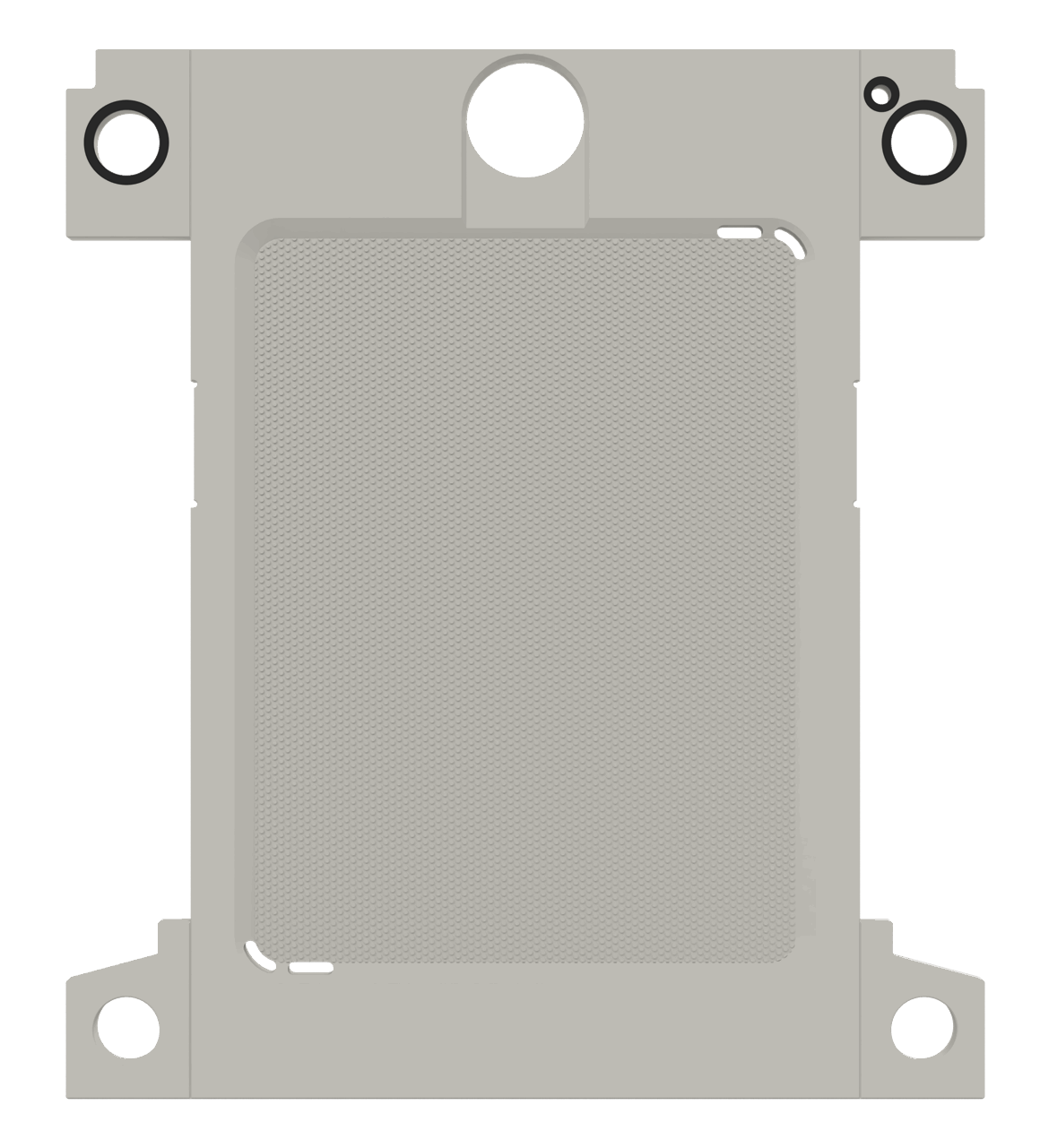

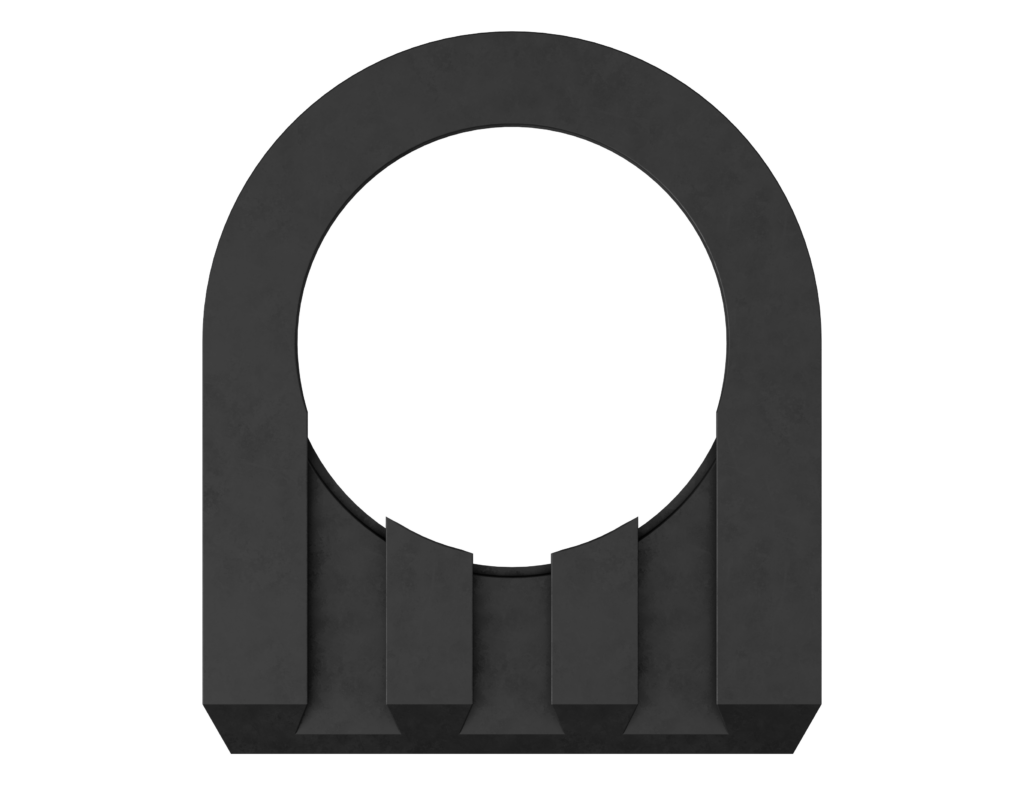

Tailor Made Recessed and Membrane Plates

Our compatible filter press plates are designed for the toughest conditions in the mining industry. Built to meet the highest standards of durability and filtration efficiency, these plates are fully interchangeable with original filter press plates, ensuring seamless integration with existing systems. Manufactured from high-strength, corrosion-resistant materials, they are engineered to perform under high pressure and with harsh chemicals, achieve superior dewatering efficiency and minimal maintenance expenses with our high-quality, 100% virgin polypropylene filter plates and membranes.

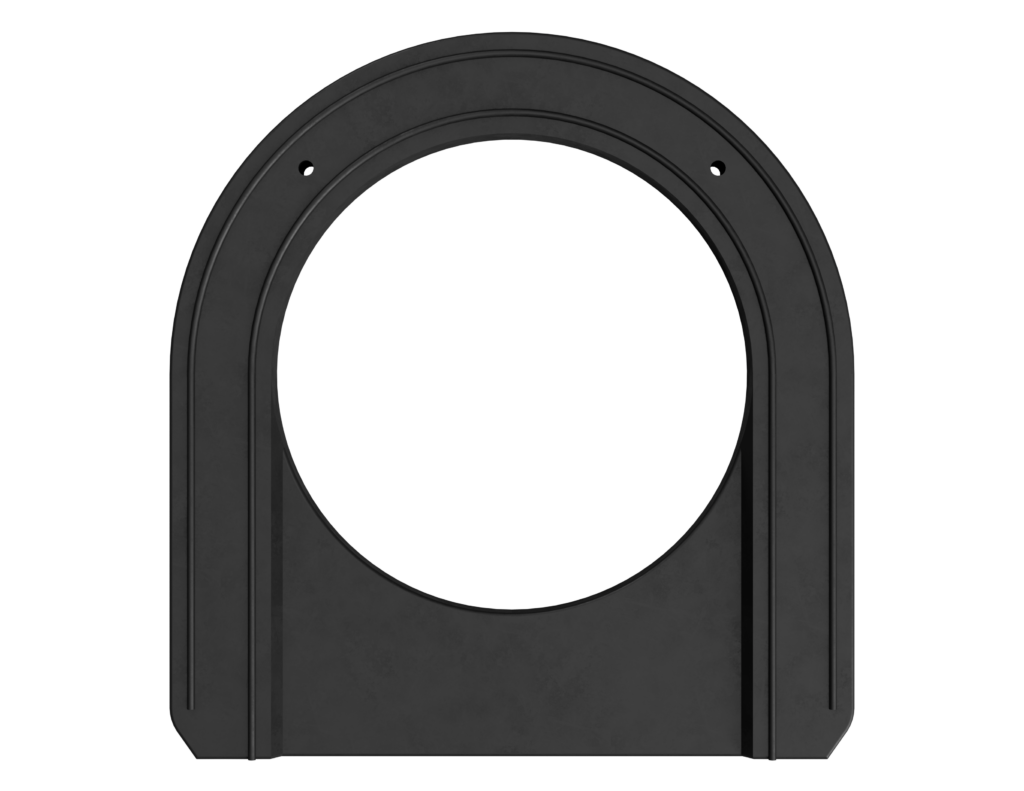

Performance Plates Design

Our compatible filter press plates are designed for the toughest conditions in the mining industry. Built to meet the highest standards of durability and filtration efficiency, these plates are fully interchangeable with original filter press plates, ensuring seamless integration with existing systems. Manufactured from high-strength, corrosion-resistant materials, they are engineered to perform under high pressure and with harsh chemicals.

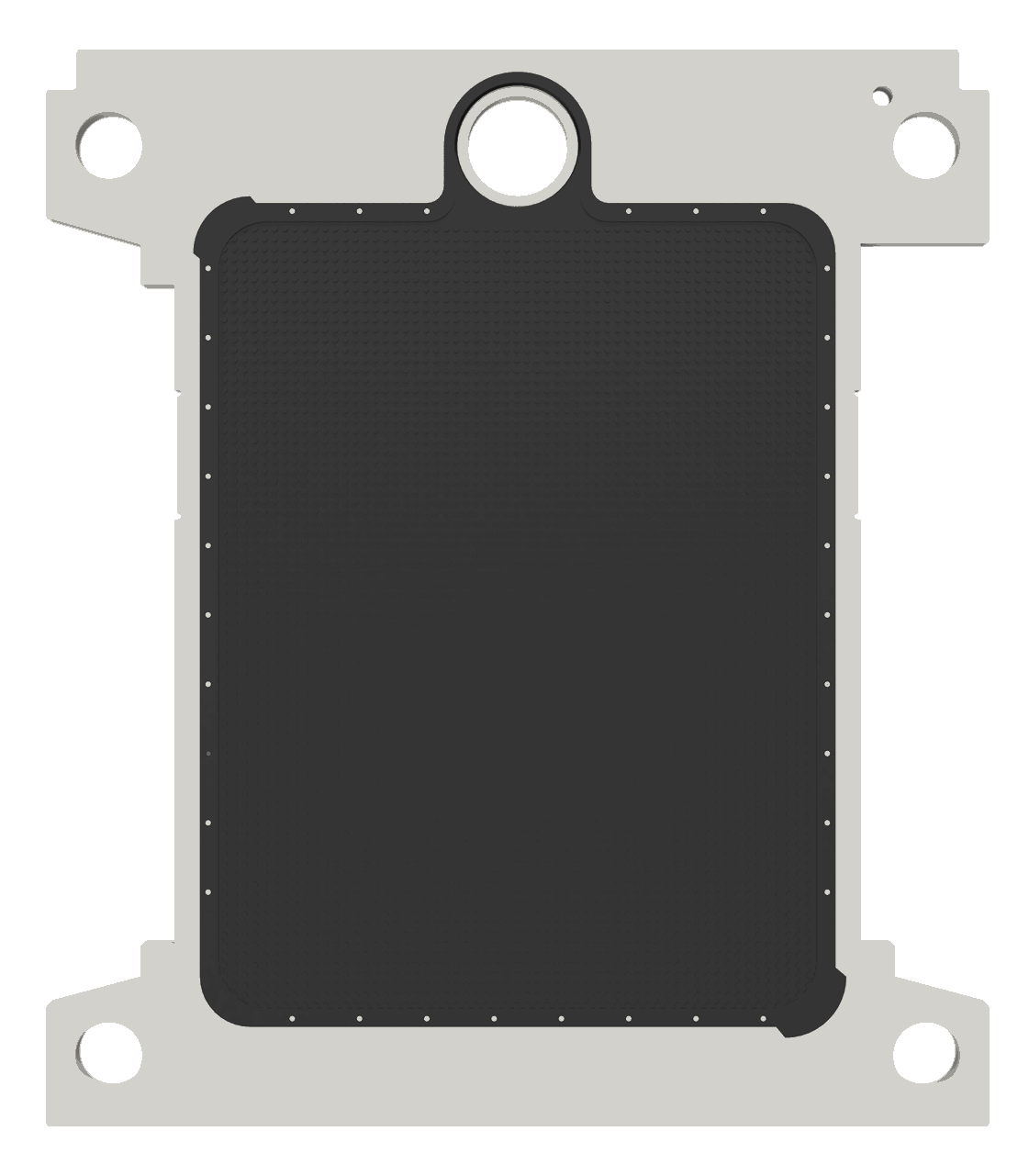

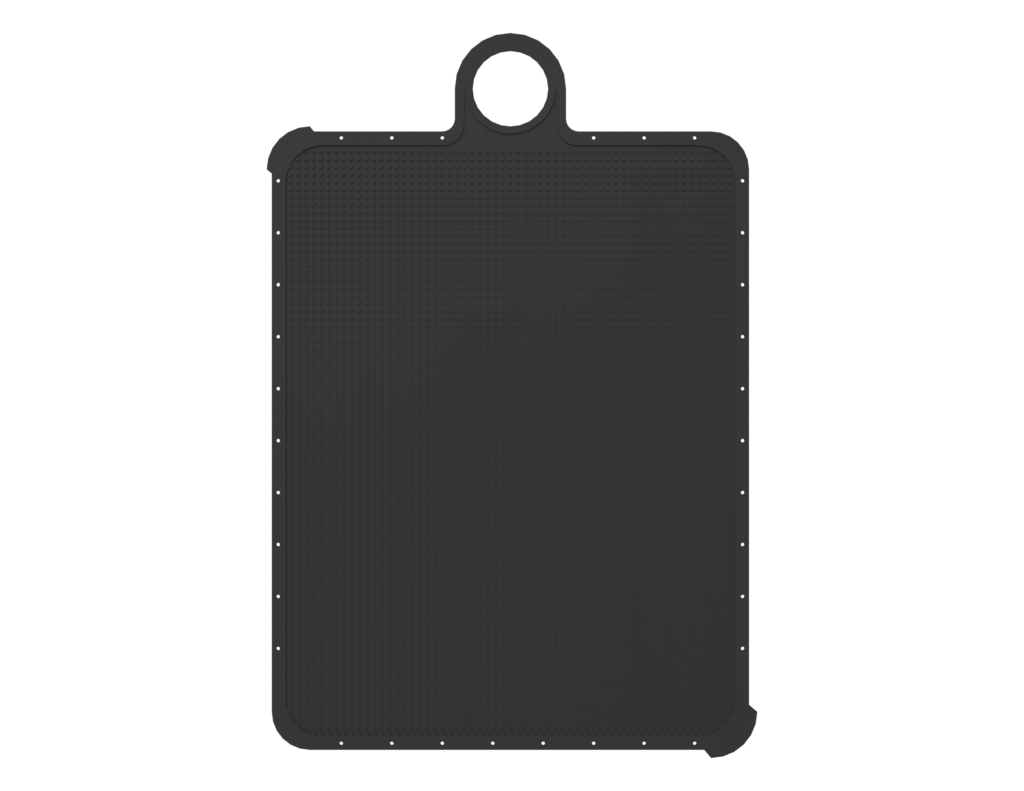

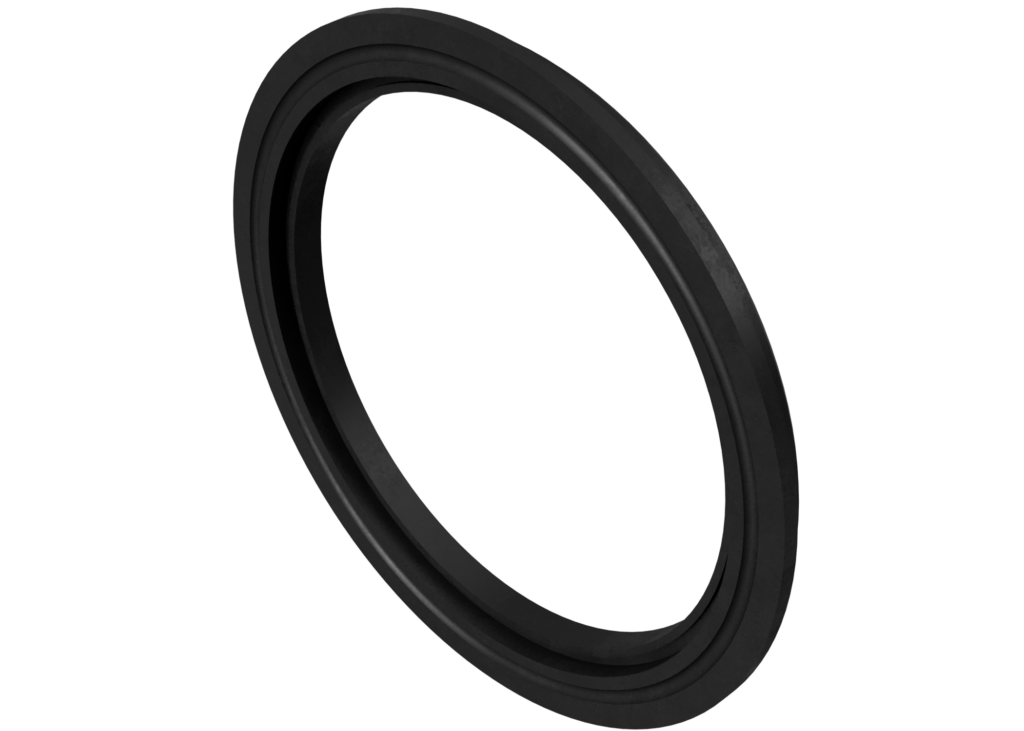

Membrane Plates

Our expertise lies in Tailings Management reducing water usage and minimizing environmental impact by providing membrane plates advanced technologies for dry tailings disposal and dry ore processing. As global demand for sustainable practices grows, we offer environmentally responsible alternatives to traditional mining operations. Our dry tailings management techniques help eliminate the risks associated with tailings ponds, reduce water consumption, and prevent water contamination. By using membrane dry stacking and filtration technologies, we ensure that waste is safely and efficiently managed without the environmental risks of wet storage.

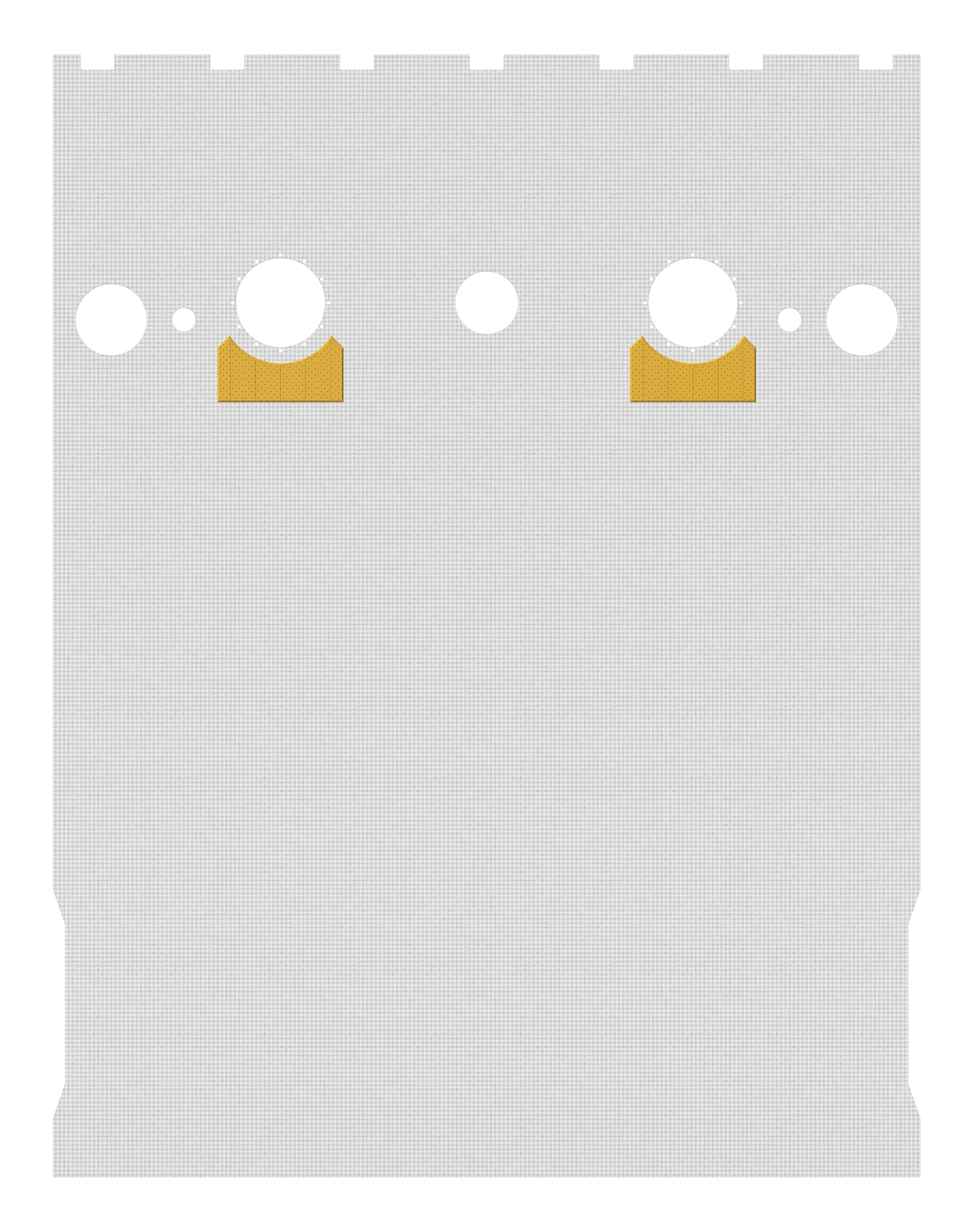

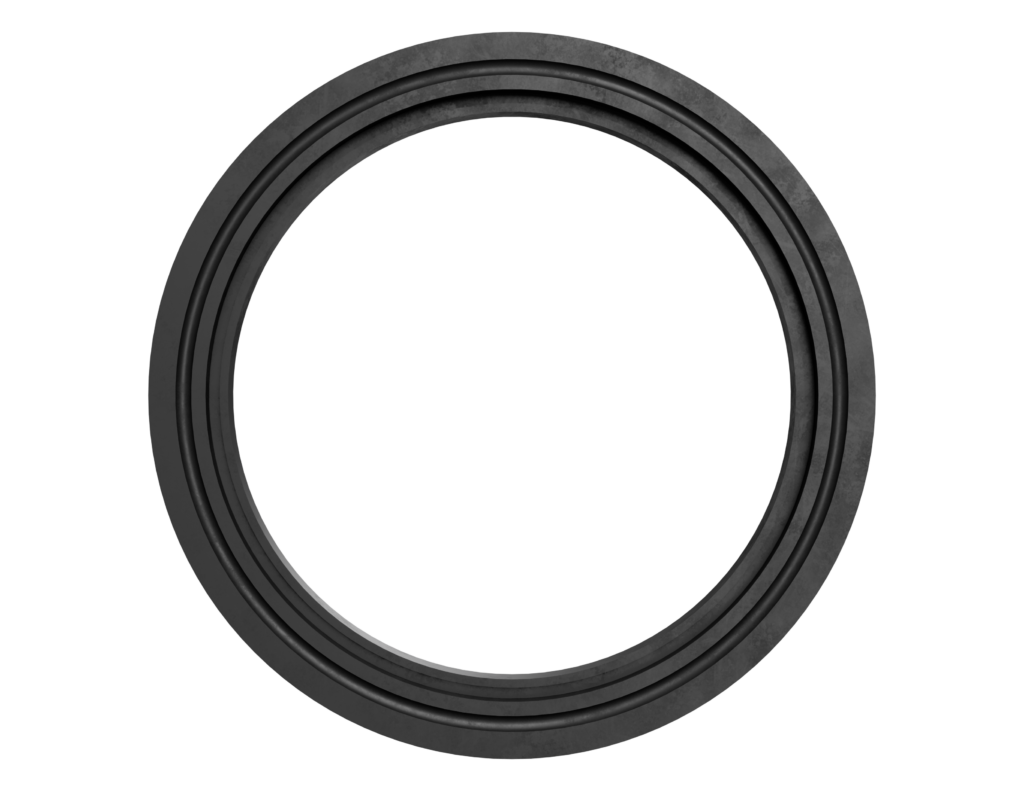

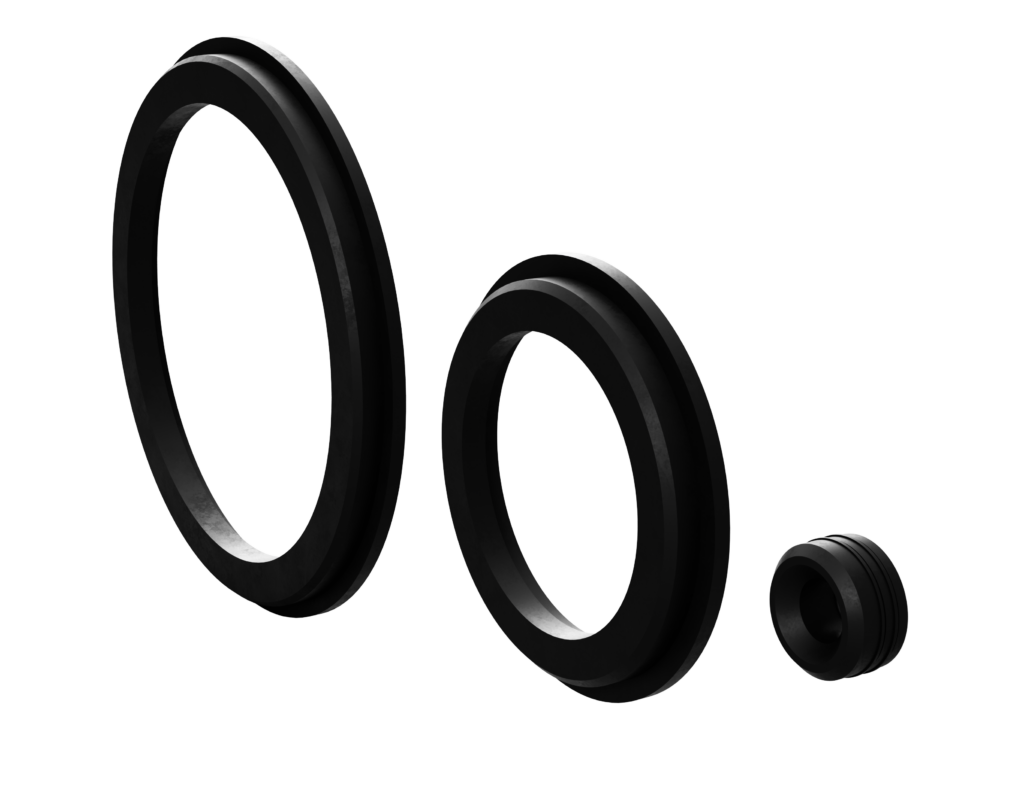

Filter Cloths

Spare Parts

Get in touch

for more details!

Get in touch

for more details

Legal headquarters

- Marechal Gomes da Costa, 630, 4150-355 Porto, Portugal

- admin@drytech.pt

Operating office

- Zona Industrial de Oiò – Av. da Estação 5 Fração A, 3770-068 PORTUGAL

- +351 914 196 161

- info@drytech.pt

Latin America

- +351 913 745 808

- ventas@drytech.pt

Asia

- +91 98364 49955

- mandal@drytech.pt

DRY TECH Unipessoal LdA

Cons. Reg. Comercial: MATOSINHOS – 517428245

Unipersonal Quota Company

NIF: PT517428245 | CS: 20000,00 Eur